Sunmise manufacturing is a professional metal die casting manufacturer in China which including aluminum die casting, zarmak die casting and brass die casting. And we guarantee that all of our die casting products are produced with high quality and low cost. Sunmise manufacturing also has the ability to add extra value to the die casting products. With the customized manufacturing systems, we handle machining, cleaning, assembly and pressure testing.

Metal Die Casting Material

Aluminum: ADC12, A380(these are our common material to produce), other meterial according to customer’s requirements

Zinc: Zamak serise

Weight can be from 0.5 oz – 500 lb

Thickness is from 0.05 – 0.5 in.

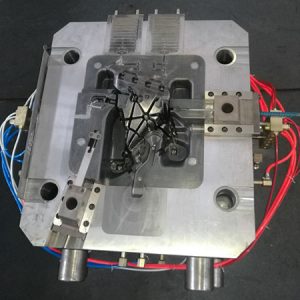

Die Casting Production process:

- Design for manufacture→ mould making →raw casting → sandblasting →rough machining or finish machining →surface treatment →product checking→ packing →delivery

- Surface treatment:

Powder coating, zinc coating,polishing, sand blasting and so on

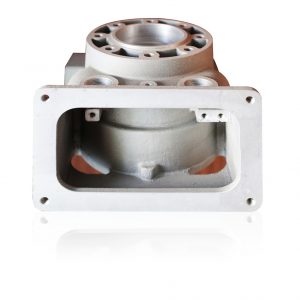

Metal Die Casting Applications:

Engine components, pump components, appliance housing and so on

Benefits of Aluminum for your Die Casting Project

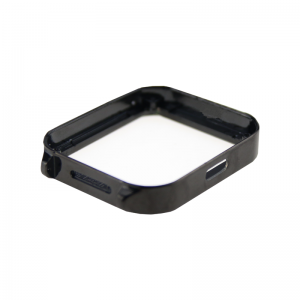

The most significant advantage of aluminum die casting compared to other processes like machining, or sheet metal forming is that aluminum can create intricate 3D designs very efficiently at a lower cost. Because of this, manufacturers are able to order customized castings that are ideal for their production needs. Aluminum die castings can turn molten metal into a near-net shape part in seconds, so machining or other operations can be eliminated.

Aluminum die castings are 100% recyclable and all of the material involved in the production of aluminum die castings is recycled. The ingot comes from recycled material and all of the excess material and any scrap castings are recycled in-house.

If you have inquires, pls contact with us with Info@sunmise.com