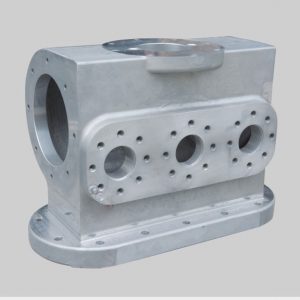

Sunmise manufacturing is one of the best gravity casting in the industry, and we guarantee that all of our gravity casting products are produced with high quality. Gravity casting is a permanent mold casting process, where the force of gravity, rather than high pressure, is used to fill the mold/die cavity with molten metal.

Gravity casting is a cost-effective casting method, as it does not require large-scale machinery. This method enables process control and produces strong and consistent good quality parts, with better surface finish and mechanical properties as compared to sand casting.

Gravity casting is therefore best suited for the production of high-volume, small scale parts with sections that are thicker than those produced by high pressure die casting, but thinner than those produced by sand casting.

Suitable material:

Aluminum(It is the most common material we produce, )Zinc,Magnesium,Copper Alloys,Graphite Molds,Iron,Steel.

Surface treatment:

Zinc plating, hot-dip galvanizing, Cr /Ni plating, , painting,anodizing, powder coating, brushing, Polishing and so on.

Packing: Carton, plastic pallet, Wooden case and so on according to custom’s requirements..

If you have inquires, pls contact with us with Info@sunmise.com