Sunmise manufacturing is very professional with injection molds which can be produced in China or exported to customers. We have exported our injection molds to US, Spain, Australia and other countries already.

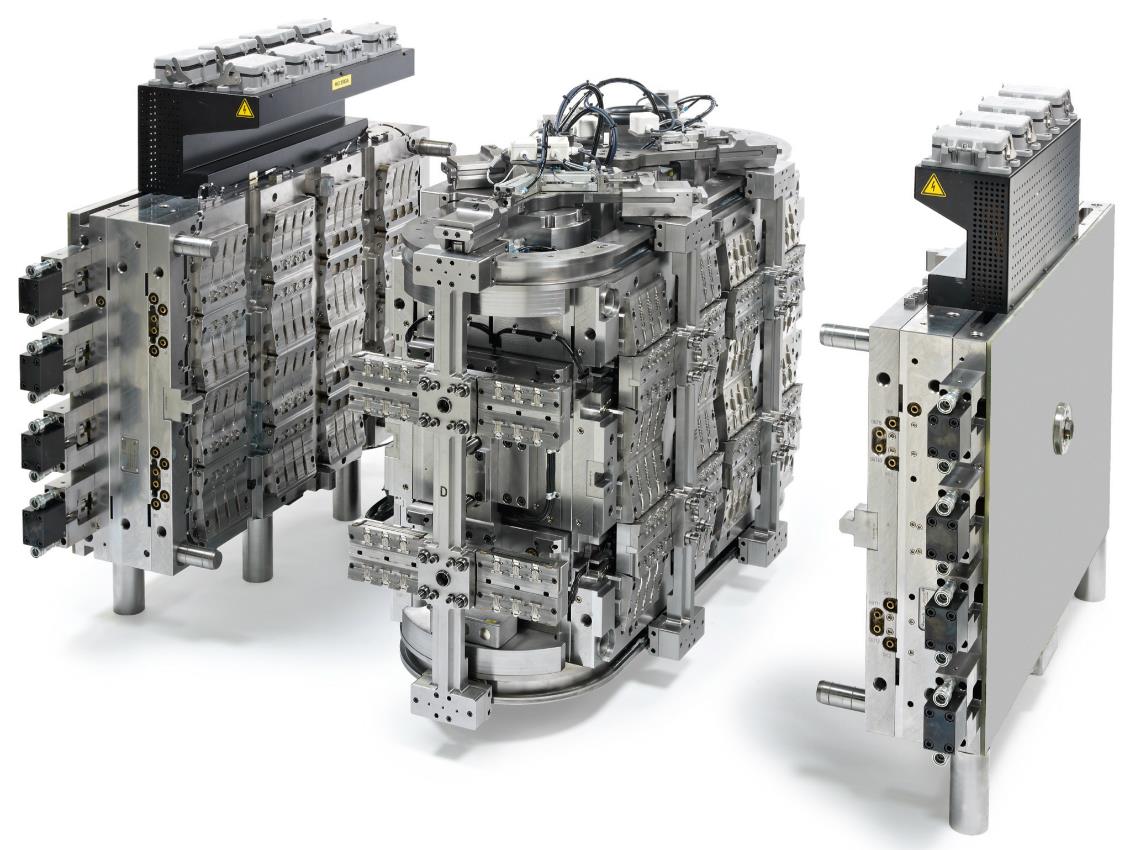

We specialize in high-tolerance, custom molds, from single cavity prototypes to large, multi-cavity production molds up to 20,000 lbs. Whether you provide approved mold designs or you work with our experienced team to develop the tooling designs you require, Sunmise manufacturing will ensure that the best molds re built for your intended application.

Inspection capabilities

Sunmise manufacturing is professional in inspection process. And main process of inspection is within the whole order below:

Sample inspection

Small batch inspection

Inspection during mass production

Final inspection for mass production

Beyond the inspection process above, we also can provide the drawing support and the inspections like material composition test and so on.

Finally, we will provide the formal inspection report to our customers. We will ensure to provide the qualified products to our customers with full trust.

Equipment introduction

To ensure the quality of our products, we have the advanced equipment and workers with rich experience to handle them. All our aims are to meet all customers’ requirements and become a strong back-up of production site in China.

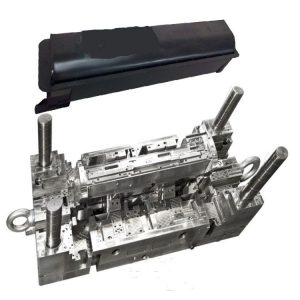

Expect the exporting molds, we can also provide the molds to be produced in China and mass production is produced together too.

Mold and Material specification

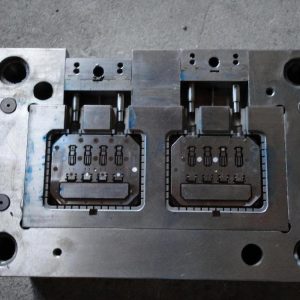

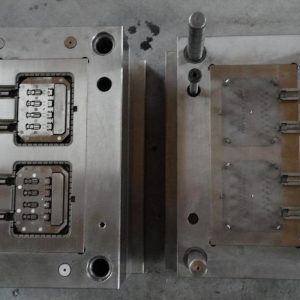

Mold Type: Traditional mold, Over mold, Insert mold, Double color mold, Cold runner mold, Hot runner mold.

Mold Base: LKM, HASCO, DME, etc. (or other brand as customer require)

Mold Core & Cavity Material :S136H, P20, 718H, NAK80, 8407, 2083,2343,2767 etc. ( or other brand that customer prefer)

Mold Warranty Life: 300, 000-1, 000, 000 shots (According to customers’ requirements)

Project Management: Design and engineering support, mold trial report, testing report (FAI, Cpk, PPAP, etc. )

Machining Equipment: Injection Molding– Injection molding machines(ranging from 50T to 1200T), Mold Workshop-imported CNC, Wire-cutting, EDM, rough machining machines, Secondary processing–Painting and printing lines and assembly lines.

Product Material: PC, PP, PBT, ABS, PE, ABS+PC, PPO, PVC, PA66, PA6, POM and so on.

Secondary Process After Molding:

- Printing:Silk-Screen Printing, Tempo Printing, Laser Engraving, Label Application

- Assembly:Manual, Semi-Automated, Fully Automated, Clean Room

- Welding:Ultrasonic Welding, Vibration Welding, Laser Welding

- Testing:Dimensional Testing (CMM), Leak Testing, Dielectric & Electric Testing, Optical Testing

Application:

- Automotive

- Medical

- Household Electrical Appliance

- Fast Moving Consumer Goods

Common additives added into material:

UV inhibitors and Flame Retardants.

Packing: Carton, plastic pallet, Wooden case and so on according to customs requirements

If you have inquires, pls contact with us with Info@sunmise.com